Nowadays, automatic gears are growing more widespread. This popularity is quite understandable; it is much more convenient in everyday use, and many of their problems of the first years of release have long been resolved. Improved automatic transmissions can be extremely fast (gear changes in 50-60 ms as in Porsche) and extremely efficient (not inferior in fuel economy to standard transmissions).

A lot of car enthusiasts clearly cannot master the "mechanics" and subtleties of gear shifting, so they, without hesitation, switch to vehicles with an automatic gearbox. But here, you must bear in mind that these parts can be different, and each type has its own features. That is why when the question of choosing a vehicle comes up, many usually think about which transmission to give preference to. Previously, it was a little easier since the decision was based on only two varieties of this automobile part an automatic transmission or a mechanical one.

So what are the automatic transmissions? What are their differences?

There are different main varieties of automatic transmissions:

- Dual Clutch (DCT)

- Continuously Variable (CVT)

- Automatic Manual (AMT)

Consider the features, profits, and drawbacks of each kind of such essential part as automatic transmissions that are available today for sale.

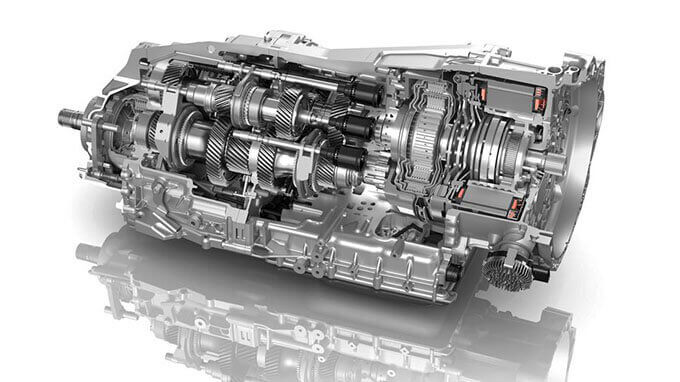

Dual Clutch Transmission

This model is based on a double shaft, which is not in the mechanical one. In a conventional manual gearbox, all gears are mounted on the same shaft, while in a dual-clutch transmission, the first clutch transfers torque to the outer shaft and the second to the inner shaft. As a result, the first is responsible for even, and the second for odd transfers. In other words, it turns out that in one transmission, they are like two gearboxes while they work alternately. The transmission control function is assigned to the automation and hydraulics. There is no torque converter in DCT.

Pros:

- Smooth gear shifting without any jerking.

- Profitability. Compared to conventional automatic transmissions, this type uses up to 10% less fuel.

- Excellent dynamics, thanks to instant shifting without loss of power and torque.

- The ability to independently switch speeds without the participation of automation.

- The dual-clutch transmission is ideally suited to powerful engines of 200 hp or more.

Cons:

- The main disadvantage of the Dual Clutch type is the complexity of the design and all the elements that make up the box, as a result of which the price of servicing parts for transmission and repairing DCT is quite high.

- Due to the complexity of the design and the relatively recent appearance, there are certain difficulties in finding high-quality service and repair services.

- The most successful dual-clutch transmission is the DSG (Direct Shift Gearbox).

How did DCT come about?

The dual-clutch box, like many other inventions, came from sports, more precisely from the racetrack. The first attempt to create a double-clutch transmission belongs to the Frenchman Adolphe Kegresse. Back in 1939, the world-famous designer tried to apply his development to the legendary Citroen Traction. But, unfortunately, the know-how remained an unfulfilled project, never reaching the conveyor. Later, in the 80s of the 19th century, Porsche engineers still managed to create a gearbox capable of changing gears under power without releasing the gas. In racing, this invention has been incredibly successful, as even the fraction of a second that is lost when the speed is reduced during a gear change can decide the outcome of a race. Simply put, the turbo engines switched to higher gears without changing the pressure in the turbine without losing torque.

How does DCT work?

The principle of operation of the Dual Clutch is based on "anticipating" or preparing the next gear; for example, when you set off in first, the transmission had already started preparing the "second" gear. When a gear change occurs, the first clutch opens, and the second clutch closes. Parts of an automatic transmission monitor the gas pedal and assume that acceleration is taking place, accordingly preparing the next gear. In general, this type monitors not only the "gas" pedal, in addition to the accelerator, but it is also taken into account:

- rotation speed of transmission shafts;

- wheel speed;

- gear lever position;

As a result, shifting occurs with lightning speed due to the fact that the clutches remain closed for only a few fractions of a second, and the motor continues to remain connected to the drive wheels without losing torque.

DCT is essentially a mechanic without one pedal, the clutch pedal. Both the automatic and the driver can shift gears utilizing the selector (gear lever) or with the help of special paddle shifters.

Continuously Variable Transmission

Such variety is often referred to as CVT. This automatic transmission has big differences over the previous type of this spare part. Technically, there is no such thing as "gear shifting"; that is why this gearbox has such a name. The gear ratio in such an automatic transmission changes continuously and smoothly, allowing you to "squeeze" the maximum power out of the engine.

Pros:

- The main advantage of this type, which distinguishes it from other automatic transmissions, is the efficient use of the power of the engine parts due to the ideal combination of the load on the car with the crankshaft speed. As a result, maximum fuel economy is achieved, the absence of any jerks, etc.

- This gearbox also has excellent dynamics. The car reaches the required speed much faster than with other gearboxes.

- In addition, with such a gearbox, you can notice the presence of a smooth ride, which provides increased comfort in driving a car.

- Other advantages of the CVT include lower weight and efficiency.

Cons:

- The main disadvantage of the CVT is the monotony of the "sound". The intense acceleration of the car takes place with the same constant engine sound, which not all drivers can withstand. In new models, they tried to solve this problem by creating "pseudo" transmissions, when parts of an automatic transmission strive to imitate the operation of classic automatic transmissions.

- Don't forget about the expensive service. Continuously Variable Transmission, like parts for this transmission, is not so popular, as a result of which the cost of service increases quite dramatically.

- One of the essential parts of this automatic transmission, the belt, requires to be replaced after a mileage of 100-150 thousand km, and this is an additional cost. If you are looking for affordable transmission parts for sale, you can find them on PartSouq.

- This sort of transmission required special oil, which is suitable for the individual model. Such oil is also not cheap.

How did CVT come about?

The first who thought about the principle of the CVT and created it was the most mysterious inventor Leonardo da Vinci back in 1490. But this notion was patented only in the 19th century (in its second half). It is noteworthy that the first operational vehicle with such a gearbox was created 500 years after its invention in the 50s of the twentieth century. For the first time, such a transmission was installed on DAF cars (at that time, the company was still specializing in car and truck creation). Later, a similarity of transmissions began to be displayed for sale installed on Volvo cars, but this type of transmission did not receive much popularity. But at the present time, CVT is in great demand and all because of its modern principle of operation.

How does CVT work?

In principle, the CVT, unlike AMT, does not have variable gears, which in turn means that when the car is moving, the usual jolts are not observed when shifting gears, and the speed gain has a smooth and precise course. The peculiarity of the work of parts of this automatic transmission on a car is a gradual change in torque on the drive and driven disc. The movement starts gently, unlike other types of gearboxes. Such work of automatic transmission parts in the car gives the impression that a powerful electric motor is installed in it. The speed is picked up smoothly, without the presence of extraneous noise. Therefore, the CVT does not need a gearshift switch, thanks to which the car accelerates much faster than with other transmissions.

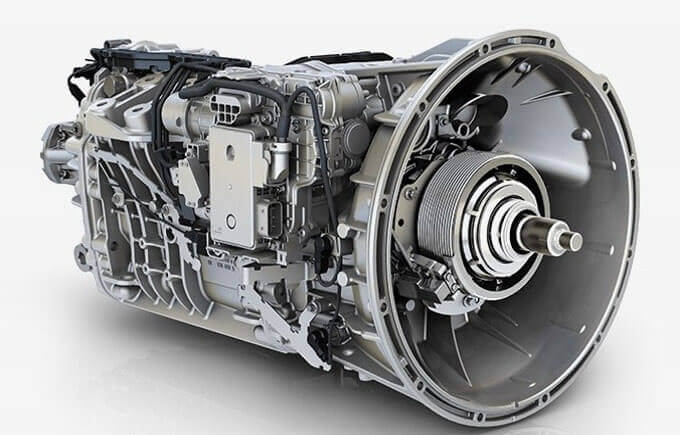

Automatic Manual Transmission

The next type is AMT. All automakers call it differently: Porsche Getrag (or PDK), Škoda and Volkswagen have DSG (Borg-Warner), Audi S-tronic. Structurally, parts of an automatic transmission are very similar to parts from a standard manual transmission. It has a clutch (or several) and shafts for transmitting power from the motor. In the case of a pair of clutches, one of them is responsible for the even gears, and the second for the odd ones. As soon as the electronics conclude that it is necessary to switch, the disc of one clutch opens smoothly, and the second, on the contrary, closes. The main difference from the manual box is fully automatic control.

Pros:

- This kind of gearbox is one of the cheapest units in production and maintenance compared with other automatic transmissions. Therefore, you can easily find parts for this transmission at affordable prices for sale.

- The automatic transmission principle prevents overloading the motor due to incorrect shifting.

- No loss of engine power due to the minimum interval between gear changes.

- Other benefits include reduced fuel consumption, low AMT weight, and operation that does not require special driving skills.

Cons:

- The main disadvantage of the device is considered to be jerks during gear changes; this is due to the rather high load on the clutch assembly. Many drivers operating this type of transmission are not even aware that reducing the load and increasing the clutch life may be a small nuance associated with shifting the gear to neutral at traffic lights.

- Although the maintenance and manufacture of this automatic transmission and the parts for it are low in price, it will still be costly and difficult to fix in the event of a failure.

- In addition, limitations involve enhanced fuel consumption when compared to a manual transmission. There is also an exception to towing a car, a rather small resource before repair, and there is no possibility of engine braking.

How did AMT come about?

The first AMTs began to be installed on cars in the 1990s. In fact, such transmissions exhibited for sale were ordinary manual transmissions, but the gears and clutch in them were switched by hydraulic or electric drives. These units were installed on the cars of many automakers and represented a cheap alternative to the more costly automatic transmission parts. Today, automakers around the world are using the second generation of AMT, the so-called Direct Shift Gearbox (DSG). It is the peculiarity of the work of the parts of this sort of automatic transmission that allows you to get beneficial advantages while driving.

How does AMT work?

The specificity of the functioning of the DSG gearbox is that while one gear is working, the next one is already completely ready for a change. Let's consider its work on the example of the Volkswagen Group DSG gearbox. The box has two output shafts with driven gears and synchronizers located on them like the six-speed mechanic transmission of the Golf. The trick is that there are also two input shafts: they are inserted into each other. All of the shafts is joined to the engine via a separate multi-plate clutch. The second, fourth, and sixth gears are fixed on the external input shaft, on the internal- the first, third, fifth, and reverse gears.

Let's say the car starts to accelerate from a standstill. The first gear is engaged (the clutch blocks the driven gear of the first gear). The first clutch is closed, and the torque is transmitted to the wheels via the internal input shaft. The car starts moving. But simultaneously with the inclusion of the first gear, smart electronics predicts the subsequent inclusion of the second gear and blocks its secondary gear. Thus, two gears are engaged at once, but jamming does not occur; the drive gear of the second gear is located on the outer shaft, the clutch of which is still open. Due to this, ATM DSG works as quickly as possible, and even a professional driver will not be able to change gears so quickly on a standard transmission.

Which automatic transmission to choose?

This question cannot be answered unequivocally, but if you follow the trends in the auto industry, it is easy to see that the most promising manufacturers consider AMT with two clutches. CVT and DCT are in second place. But, we believe that the choice of transmission should also be based on the class of the car and who will drive it and how much. For example, if you prefer a relaxing driving style, then the classic DST will triple you, and if you like fast and aggressive driving, we advise you to pay attention to ATMs. In sport mode, their "rate of fire" can rival that of a real race car driver. And for a small car, a regular CVT will just fit.

Every type of automatic transmission has its own specific advantages and disadvantages. However, over time and technology development, problems with automatic transmission parts become less and less obvious. In addition, regular maintenance of the car should be carried out in order to get only pleasant sensations from the purchase. As a result, by purchasing high-quality parts for transmission, you can always be content with your choice to the fullest! Stay with PartSouq and monitor the condition of your vehicle properly.

FAQ

- What are all the parts of an automatic transmission?

Major parts of the automatic transmission involve torque converter, manual transmission, and control system. The torque converter is designed to transfer and change torque from the engine to the manual transmission, as well as reduce vibrations. The design of the torque converter includes pump, turbine and reactor wheels, lock-up clutch, and freewheel clutch. The torque converter is housed in its own housing. Also, automatic transmissions have the main gear and differential in their design when installed on front-wheel-drive cars.

- Can you rebuild an automatic transmission?

Defective automatic transmissions do not need to be replaced - repairs are almost always possible. But this complex auto component can sometimes cost more than a new mini car. Repairing automatic transmission parts is often cheaper than buying a new transmission. In order to save on repairs and buy OEM parts, choose PartSouq, and you will get a reasonable price for transmission parts for sale, reliability, and durability.

- What are the symptoms of automatic transmission problems?

Symptoms of a malfunctioning automatic transmission are:

- Perceptible vibration on the body during or beginning of movement;

- Uncharacteristic knocking, grinding, burning smell;

- Sticking or delay in gear shifting, a complete absence of one / several gears;

- Transmission slipping or engine is revving high;

- Check on the dashboard;

- The car has no power;

- Why can automatic transmission break down?

Most often, the main reasons for automatic transmission failure are untimely maintenance in the form of oil changes, consumables, and improper vehicle operation. In the automatic transmission, worn internal parts fly, which in most cases change quite easily. For example, the most common failure is a control unit or torque converter. In this case, for repair, it is enough to replace the failed parts. To prevent this from happening, use proven transmission parts to keep the car in good condition. PartSouq is one of the few sites that has transmission parts for sale at affordable prices.