Electric and hydraulic power steering in a car is a device that is needed to turn the steering wheel easier when performing maneuvers. Its presence allows you to drive the car with great comfort.

The spool is considered the main part of the steering system; its position determines the process of functioning of the assemblies and elements of the system. Regardless of the type of movement of the spool, which can be axial or rotary, there are no differences in the principle of action. When the steering wheel is centered, the spool is held in place by centering spring elements. This action allows the oil to move freely through all system components. But provided that the valve is in the correct position.

The pumping device operates in an enhanced mode, distilling the working fluid through the system. This node always works, regardless of whether maneuvers are performed or not. The main purpose of the pumping device is precise to pump oil.

When the driver turns the steering wheel, the spool starts to move, as a result of which it closes the drainpipe; this leads to the supply of oil into one of the cylinder chambers, and the pumping procedure is performed under the influence of pressure.

At the same time, the piston and rod components, due to the movement of the fluid, turn the wheels and the valve body in the direction where the valve moves. The switchgear body can overtake the spool only when it stops moving; this indicates that the maneuver has been completed.

Then the spool element moves to its original state, the oil drain pipe is opened.

The device of the classic power steering

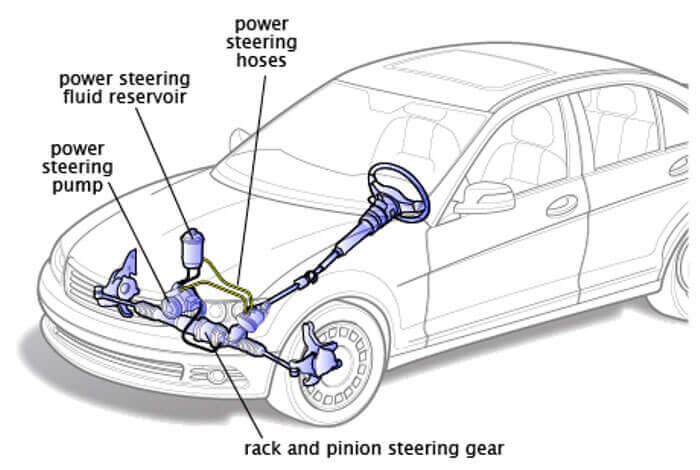

Parts of the power steering system:

- Pumping mechanism. This assembly is designed to provide the entire system with the necessary pressure for the fluid to circulate. Most modern cars use plate mechanisms due to the increased efficiency and increased resource of use. The pump itself is usually mounted on the engine, and a belt drive ensures its operation.

- Distribution unit. This mechanism is used to distribute oil and direct it to specific cylinder cavities. Depending on the system, a rotary or axial distribution mechanism can be used in the power steering. If the movements of the spool are translational, the distribution unit is equipped with an axial distributor, while the rotary valve is equipped with a rotary valve. The unit is mounted on steering components or directly on the steering shaft. This mechanism is sensitive to the presence of contaminants in the working fluid.

- Hydraulic cylinder. It is used to ensure the operation of the piston and rod when supplying fluid. Special levers are used to turn the wheels of the machine. The cylinder itself is located between the body and the drive or on the steering gear.

- Highways. Oil is moved through the pipes in the power steering system. Lines can be low or high pressure. The former is used to return the working fluid from the expansion tank to the pumping device and again to the tank after working off. The latter is designed to supply a consumable between the pumping device, the distribution mechanism, and the cylinder.

- Oil. A key part of the power steering system. The lubricant is necessary to provide power to the hydraulic cylinder from the pumping device. It lubricates all amplifier components.

- Expansion tank. The tank is designed to store consumables and circulate them. Equipped with a filter device, through which the substance is purified from dirt. There are markings on the reservoir that allow you to check the liquid level.

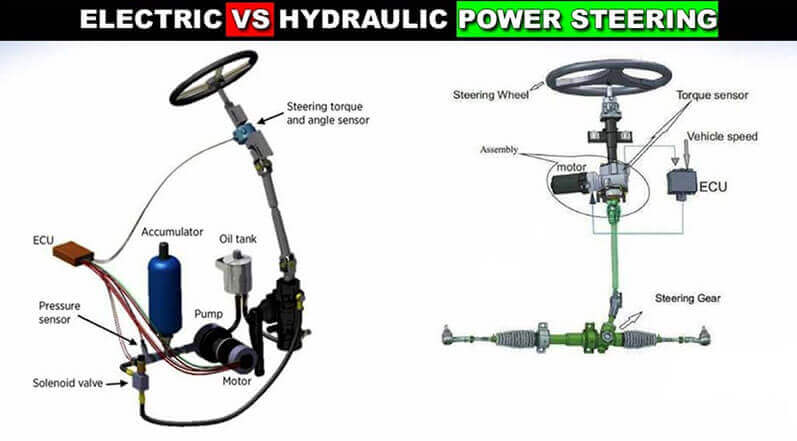

By the way, the electro-hydraulic power steering has a similar device. But the electro-hydraulic mechanism is equipped with a control module, as well as a solenoid valve. The system can also be supplemented with a speed controller.

How does electric power steering work?

There is no working fluid in the EPS system. The electric amplifier does not always function, but only when performing maneuvers. The system’s power unit provides torque, which is determined by the torque on the steering unit. This parameter is measured using a special part of the steering wheel, the controller that transmits information to the control module of the system. The block is designed to calculate the required parameter of the activation power of the system motor, taking into account the position of the steering wheel.

The steering angle measurement procedure is carried out using a controller built into a switch mounted under the steering wheel. The rotary device of the electric motor has a controller that measures the mechanism’s speed and then transmits the data to the ECU; this is required for the module to determine the speed at which the node is scrolling. The EUR control module takes into account many readings when calculating the required effort on the electric motor.

This parameter is determined by:

- rudder torque value;

- the speed of the machine;

- revolutions of the power unit, angle, and speed of the steering wheel.

In the future, the effort from the motor is fed to the rail using drive gear and a worm gear. Moving the rail is carried out as a result of several efforts; this is facilitated by the steering wheel, as well as the electric motor of the EUR system, which is controlled by an electronic module.

When you move the steering wheel, the torsion bar is twisted. The electronic module calculates the applied force by the change in position of the constituent elements of the controller. The steering mechanism detects the deflection of the steering wheel. These parameters are processed by a microprocessor module that interacts with the machine's ECU.

Taking this information into account, the microprocessor unit calculates the required force and then supplies the power of the required value to the motor. The latter performs the movement of the rudder shaft or rack.

Which is better: electric or hydraulic power steering?

To understand which is better, we suggest that you familiarize yourself with the list of disadvantages of both systems.

Cons of electric power steering:

- the EUR cannot boast of high steering information content;

- there is a possibility of malfunctions in the EUR settings. Possible damage to the steering wheel or shaft controllers;

- spare parts for electric power steering are usually cheaper than parts for hydraulic power steering;

- there is a possibility of malfunctions while driving. If the amplifier locks up, it can lead to damage and accidents on the road. It will be problematic to align the wheels if the machine is stationary;

- the electrical component is often beyond repair. The rudder position controllers are better not to be repaired but to be changed, since when the sensors are re-soldered, the consumer may set incorrect parameters. Because of this, the maintenance of the EUR will be more expensive;

- calibration of controllers is required periodically, and it is problematic to do this on your own. You will have to contact qualified specialists.

Cons of hydraulic power steering:

- In cars equipped with hydraulic power steering, it is not allowed to hold the steering wheel in an extreme position for a long time. This action will lead to overheating of the working fluid and breakdown of structural elements, primarily the pump;

- the power steering should be serviced from time to time. The working fluid needs to be replaced once every few years. The consumer should regularly monitor its level, diagnose the integrity of electrical circuits, lines, and pumping devices;

- power steering does not allow adjustment of operating modes taking into account driving conditions;

- power steering provides high information content of the entire system when driving at low speed. But when driving at high engine speeds, this parameter falls.

How Does Power Steering Work FAQ

- What is the pressure in the hydraulic power steering?

If the steering wheel in the hydraulic control system is in its original state, the lubricant pressure will be 5-7 bar. When the maneuver is carried out and the pumping device is activated, the pressure parameter will increase to 79-86 bar.

- Where to buy steering wheel parts?

If you need to change the power steering urgently, please contact us soon. Our shop has a huge variety of different parts for any car.

- What is the device of the electric power steering?

The main parts of the steering system:

- Electric motor, brushless devices are used on most machines.

- Servo. Different types of devices can be used. Torque-sensing controller. This sensor is considered one of the main ones; it is usually mounted on a torsion bar located in the cut of the steering shaft. At the ends of the element, two different parts of the controller are installed. Depending on the type of EUR, the sensor can be classified as optical or magnetic.

- Steering wheel movement controller.

- Control module.

- Some cars are equipped with a steering wheel speed controller.

- Where was the power steering first used?

The American engineer Francis Davis is considered to be the officially recognized designer of power steering. He worked for Pierce-Arrow, a company that specialized in the production of trucks and fire trucks. There Davis built and tested power steering on site. In 1925, he patented and demonstrated the first power steering.

The hydraulic booster proved to be excellent in military vehicles. In the post-war years, Davis still managed to install the power steering on a passenger car. At first, the power steering was installed on elite cars and then on ordinary cars. The Chrysler Corporation produced the first affordable power steering car in 1951.